©Copyright 2021 Zhangjiagang BEST Machinery Co., LTD

Designed by wonder-tech / Manage Entrance

+86-512-58719026

+86-512-58719026

BST-1800A plastic injection molding machine

shot weight :335-378 g

max opening stroke:440 MM

Space Between Stroke:480 X 460 MM

we have Imported advanced computer systems, Chinese / English interface.

You can save 100 sets of mold parameters.

Advanced clamping structure and injection parts, precision hydraulic system and circuit design.

Suitable for producing different types of precision small parts.

|

Style:

|

|

|

Condition:

|

|

|

Automatic:

|

|

|

Payments:

|

|

|

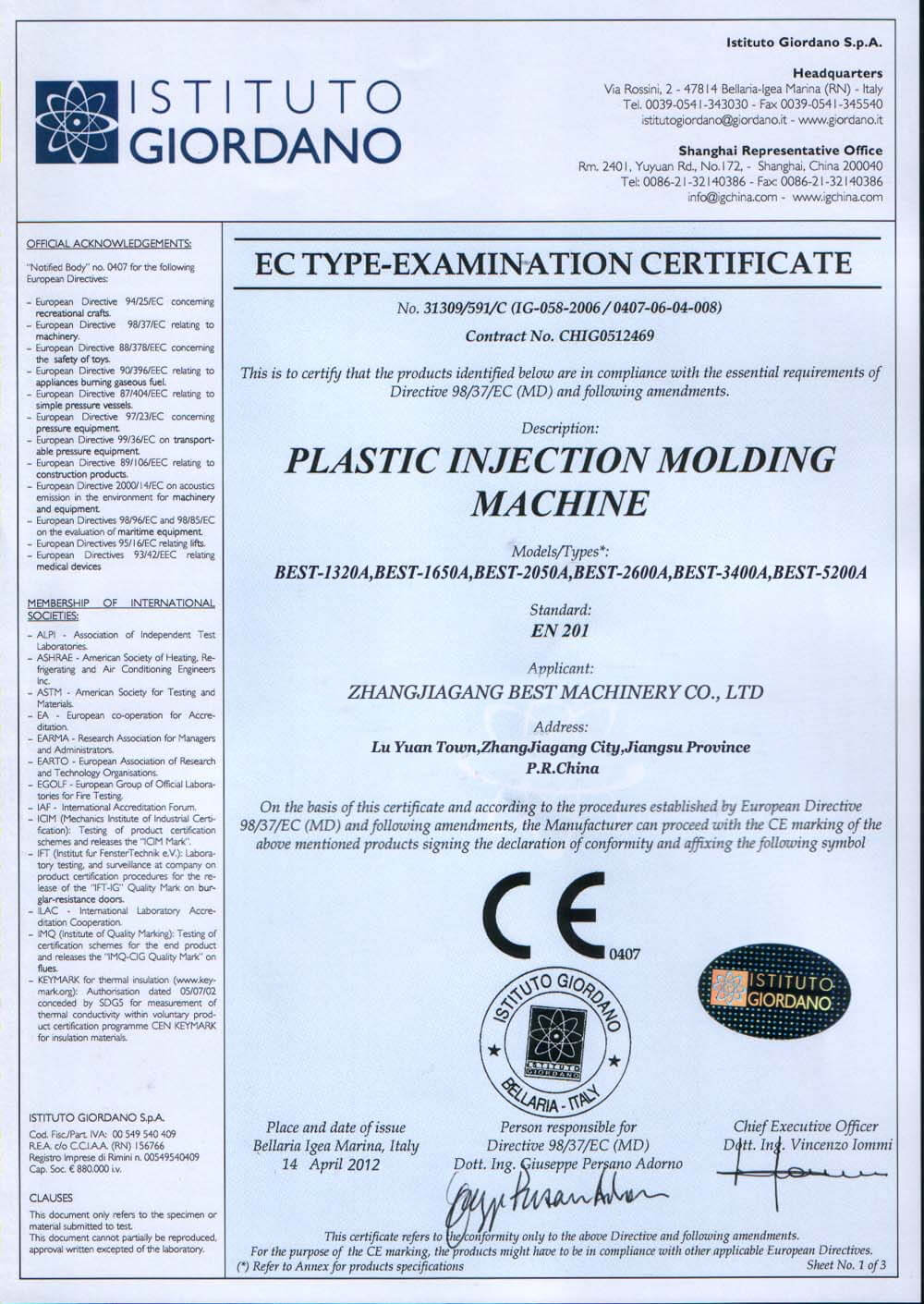

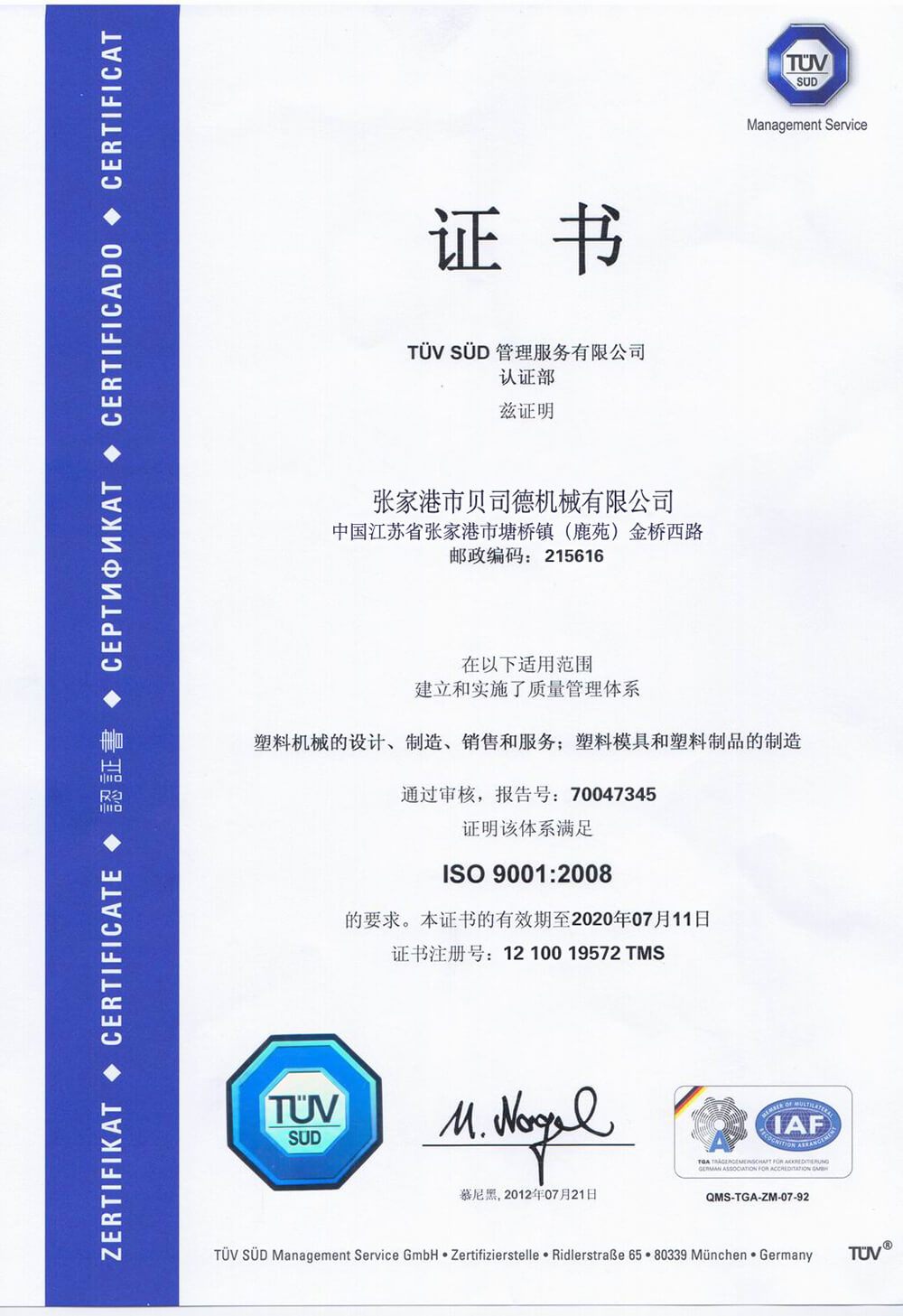

Quality:

|

|

| MODEL | BST-1800A | ||||||

| INJECTION UNIT | | A | B | ||||

| Screw diameter | mm | 45 | 48 | ||||

| Shot size(theoretical) | Cm³ | 372 | 420 | ||||

| Shot weight | g | 335 | 378 | ||||

| Injection pressure | Mpa | 168 | 148 | ||||

| Injection rate | g/s | 142 | 160 | ||||

| Screw L/D ratio | L/D | 23.1 | 21.7 | ||||

| Screw speed | r.p.m | 0-180 | |||||

| Nozzle Diameter | Srmm | 20 | |||||

| CLAMPING | | | |||||

| Clamp tonnage | KN | 1800 | |||||

| Toggle stroke | mm | 440 | |||||

| Mould Thickness | mm | 180-470 | |||||

| Space between tie-bars | mm | 480X460 | |||||

| Ejector stroke | mm | 155 | |||||

| Ejector tonnage | KN | 70 | |||||

| Ejector number | Piece | 5 | |||||

| Hole Diameter | mm | 125 | |||||

| OTHERS | | | |||||

| Heat power | KW | 11 | |||||

| Max. pump pressure | MPa | 16 | |||||

| Pump motor power | KW | 15 | |||||

| Valve Size | mm | 16 | |||||

| Machine dimension | m | 5.3X1.6X1.75 | |||||

| Machine weight | t | 5.5 | |||||

| Oil tank capacity | L | 250 | |||||